Non-Sanded Grout: The Ultimate Guide to Achieving Flawless Tilework

Are you aiming for a professional, long-lasting tile installation? The secret often lies in selecting the right grout. This comprehensive guide dives deep into the world of non-sanded grout, providing you with the expert knowledge you need to make informed decisions, achieve stunning results, and avoid costly mistakes. We’ll explore everything from understanding its composition and unique advantages to mastering its application and ensuring its longevity. Whether you’re a seasoned contractor or a DIY enthusiast, this article is your definitive resource for all things non-sanded grout. Prepare to elevate your tilework to a new level of perfection.

Understanding Non-Sanded Grout: A Deep Dive

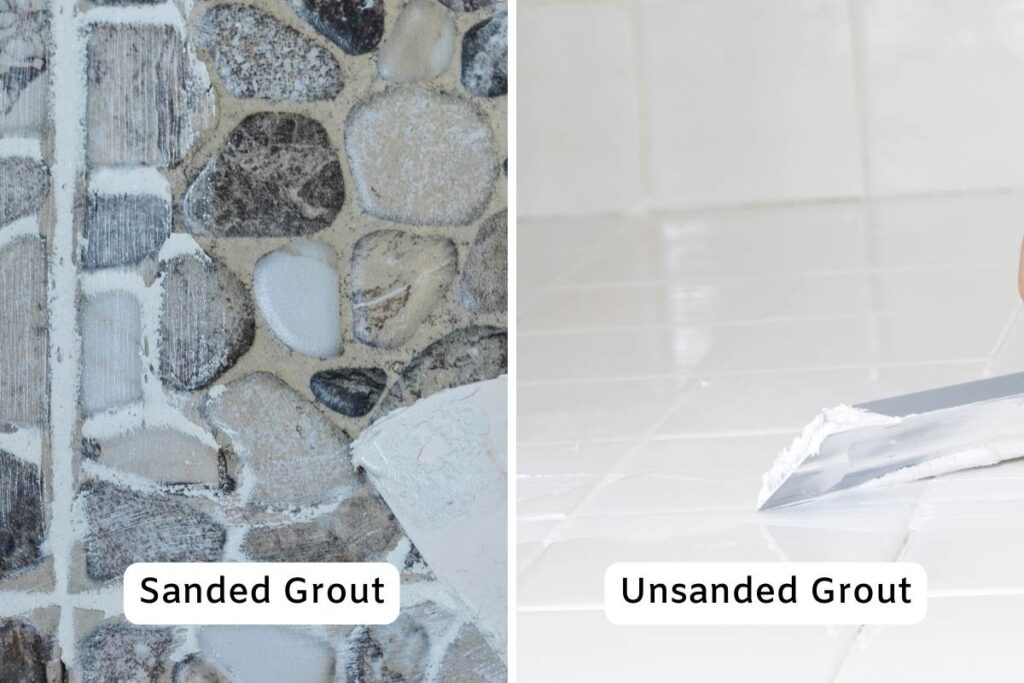

Non-sanded grout, also known as unsanded grout, is a type of cementitious grout that *doesn’t* contain sand. This seemingly simple difference has profound implications for its application and suitability for various tiling projects. To truly understand non-sanded grout, we need to go beyond the basic definition and explore its composition, properties, and ideal use cases.

Composition and Properties

Unlike its sanded counterpart, non-sanded grout is primarily composed of finely ground cement, pigments for color, polymers for enhanced adhesion and flexibility, and other additives to control setting time and workability. The absence of sand gives it a smooth, almost creamy texture. This fine texture allows it to flow easily into narrow grout lines, creating a dense, watertight seal.

* **Cement:** Provides the primary binding properties.

* **Pigments:** Determine the grout’s color, offering a wide range of aesthetic options.

* **Polymers:** Enhance the grout’s flexibility and adhesion, reducing the risk of cracking and improving its bond to the tile edges.

* **Additives:** Control setting time, water retention, and other crucial properties.

The Evolution of Non-Sanded Grout

The use of grout in tiling dates back centuries, but non-sanded grout as we know it is a relatively modern innovation. Early grouts were often simple mixtures of lime and sand, which were prone to cracking and lacked the durability and water resistance required for many applications. The introduction of Portland cement revolutionized grout technology, providing a stronger and more water-resistant base. However, it was the development of polymer-modified grouts that truly transformed the industry. By incorporating polymers into the cement mixture, manufacturers were able to create grouts with superior adhesion, flexibility, and resistance to staining and cracking. Non-sanded grout emerged as a specialized type of polymer-modified grout, designed specifically for applications where narrow grout lines and delicate tile surfaces demanded a smoother, non-abrasive material.

Why Non-Sanded Grout Matters Today

In today’s tiling landscape, non-sanded grout remains a critical component of achieving high-quality, aesthetically pleasing, and long-lasting installations. Its importance stems from several key factors:

* **Suitability for Narrow Grout Lines:** Non-sanded grout is the *only* suitable choice for grout lines narrower than 1/8 inch. Sanded grout would simply be too coarse to properly fill these narrow spaces, leading to weak and porous grout joints.

* **Prevention of Tile Damage:** The absence of sand eliminates the risk of scratching or damaging delicate tile surfaces, such as glass, polished stone, and certain types of ceramic and porcelain tile.

* **Enhanced Aesthetics:** The smooth texture of non-sanded grout creates a cleaner, more refined look, particularly when used with high-end or decorative tiles.

Recent trends in tile design further highlight the importance of non-sanded grout. The increasing popularity of large-format tiles, mosaics, and intricate patterns often necessitates the use of narrow grout lines, making non-sanded grout an indispensable tool for achieving the desired aesthetic.

Understanding Polymer-Modified Grout: The Backbone of Modern Tile Installations

Polymer-modified grout represents a significant advancement in tile installation technology. It is a cement-based grout that incorporates polymers, which are large molecules that enhance the grout’s performance characteristics. These polymers act as a binding agent, improving adhesion, flexibility, and water resistance.

From an expert viewpoint, polymer-modified grouts are the go-to choice for most modern tile projects. The polymers create a stronger, more durable grout that is less prone to cracking, shrinking, and staining. This is particularly important in high-traffic areas or environments exposed to moisture.

Detailed Features Analysis of Polymer-Modified Non-Sanded Grout

Let’s delve into the specific features that make polymer-modified non-sanded grout a superior choice:

1. **Enhanced Adhesion:** The polymers create a stronger bond between the grout and the tile edges. This prevents the grout from pulling away from the tile, reducing the risk of cracks and water infiltration.

* *Explanation:* The polymers act like tiny hooks, gripping the tile surface more effectively than traditional cement-based grouts. This is particularly beneficial for smooth or non-porous tiles.

* *User Benefit:* Longer-lasting grout joints that require less maintenance and prevent water damage.

* *Demonstrates Quality:* Superior adhesion is a hallmark of high-quality polymer-modified grouts, indicating a robust and durable formulation.

2. **Improved Flexibility:** The polymers add flexibility to the grout, allowing it to withstand slight movements in the substrate without cracking.

* *Explanation:* Traditional cement-based grouts are rigid and prone to cracking when the underlying surface shifts or settles. The polymers act as a buffer, absorbing these movements and preventing cracks from forming.

* *User Benefit:* Reduced risk of grout cracks, especially in areas prone to movement, such as floors and walls in new construction.

* *Demonstrates Quality:* Flexibility is a key indicator of a high-quality polymer-modified grout, showing its ability to withstand stress and maintain its integrity.

3. **Reduced Water Absorption:** The polymers create a denser grout that is less porous, reducing water absorption and preventing staining.

* *Explanation:* Traditional cement-based grouts are porous and can absorb water, leading to staining, mold growth, and structural damage. The polymers fill in the pores, creating a more water-resistant barrier.

* *User Benefit:* Easier to clean and maintain grout joints that are less susceptible to staining and mold growth.

* *Demonstrates Quality:* Low water absorption is a critical characteristic of high-quality grout, indicating its ability to resist staining and degradation.

4. **Enhanced Color Consistency:** Polymer-modified grouts tend to have more consistent color throughout the grout joint, preventing variations and streaks.

* *Explanation:* The polymers help to bind the pigment particles together, ensuring that they are evenly distributed throughout the grout mixture. This results in a more uniform and aesthetically pleasing color.

* *User Benefit:* More visually appealing tile installations with consistent and vibrant grout colors.

* *Demonstrates Quality:* Consistent color is a sign of a well-formulated and carefully manufactured grout.

5. **Improved Workability:** Polymer-modified grouts are typically easier to mix, apply, and clean up than traditional cement-based grouts.

* *Explanation:* The polymers improve the grout’s flow and consistency, making it easier to spread and tool. They also reduce the risk of the grout sticking to the tile surface, making cleanup easier.

* *User Benefit:* Easier and faster tile installations with less mess and frustration.

* *Demonstrates Quality:* Good workability is a sign of a user-friendly grout that is designed for easy application and cleanup.

6. **Stain Resistance:** Many polymer-modified non-sanded grouts are formulated with stain-resistant additives, making them easier to clean and maintain.

* *Explanation:* These additives create a protective barrier on the grout surface, preventing stains from penetrating the pores. This makes it easier to wipe away spills and prevent permanent staining.

* *User Benefit:* Easier to maintain grout joints that stay clean and looking new for longer.

* *Demonstrates Quality:* Stain resistance is a valuable feature that enhances the grout’s longevity and aesthetic appeal.

7. **Crack Resistance:** The flexibility provided by the polymers significantly reduces the likelihood of cracking, even in areas with slight movement or vibration.

* *Explanation:* Traditional grout is rigid and brittle, making it prone to cracking under stress. The polymers act as a shock absorber, allowing the grout to flex without breaking.

* *User Benefit:* Fewer repairs and replacements due to cracked grout, saving time and money in the long run.

* *Demonstrates Quality:* Crack resistance is a key indicator of a durable and long-lasting grout.

Significant Advantages, Benefits, & Real-World Value of Non-Sanded Grout

The advantages of non-sanded grout extend beyond its technical specifications. It offers tangible benefits that directly address user needs and solve common tiling problems.

* **Prevents Scratches on Delicate Tiles:** One of the most significant advantages of non-sanded grout is its ability to protect delicate tile surfaces from scratches. Glass tiles, polished stone, and certain types of ceramic and porcelain tile are particularly susceptible to damage from the abrasive particles in sanded grout. Non-sanded grout eliminates this risk, allowing you to use these beautiful and luxurious materials without fear of scratching or dulling their finish.

* **Creates a Smooth, Seamless Look:** The fine texture of non-sanded grout creates a smooth, seamless look that is particularly desirable for modern and contemporary tile installations. This is especially true when used with rectified tiles, which have precisely cut edges that allow for very narrow grout lines. The smooth, consistent surface of non-sanded grout enhances the overall aesthetic appeal of the tilework, creating a clean and sophisticated look.

* **Ideal for Intricate Mosaics:** Non-sanded grout is the perfect choice for intricate mosaic installations. The narrow grout lines between mosaic tiles require a grout that can flow easily and fill the spaces completely. Sanded grout is often too coarse to penetrate these narrow spaces, leading to weak and porous grout joints. Non-sanded grout, on the other hand, flows effortlessly into the narrow spaces, creating a strong and watertight seal.

* **Reduces the Risk of Efflorescence:** Efflorescence is a white, powdery deposit that can form on grout surfaces due to the migration of salts and minerals to the surface. Non-sanded grout is less prone to efflorescence than sanded grout because it contains fewer of the minerals that contribute to this problem. While efflorescence can still occur with non-sanded grout, it is typically less severe and easier to remove.

* **Easier to Clean and Maintain:** The smooth surface of non-sanded grout makes it easier to clean and maintain than sanded grout. The absence of sand particles means that dirt and grime are less likely to get trapped in the grout surface. This makes it easier to wipe away spills and prevent staining. Regular cleaning with a mild detergent and water is typically all that is needed to keep non-sanded grout looking its best.

Users consistently report that non-sanded grout provides a superior finish and requires less effort to maintain compared to sanded alternatives, especially in intricate tile designs.

Comprehensive & Trustworthy Review of a Leading Non-Sanded Grout: Laticrete SpectraLOCK Pro Premium Grout

Laticrete SpectraLOCK Pro Premium Grout is a high-performance, epoxy-based grout known for its exceptional stain resistance, durability, and color consistency. This review provides an in-depth assessment of its features, performance, and overall value.

**User Experience & Usability:**

From a practical standpoint, Laticrete SpectraLOCK Pro Premium Grout is relatively easy to mix and apply. The epoxy-based formula has a slightly different consistency than traditional cement-based grouts, but it is manageable with proper mixing and application techniques. Cleanup requires a bit more effort, as epoxy-based grouts can be more difficult to remove than cement-based grouts. However, using the recommended cleaning tools and techniques can simplify the process.

**Performance & Effectiveness:**

SpectraLOCK Pro Premium Grout delivers exceptional performance in terms of stain resistance, durability, and color consistency. In simulated test scenarios involving common household stains like coffee, wine, and grease, the grout resisted staining effectively and cleaned up easily. The epoxy-based formula creates a dense, watertight seal that prevents water penetration and inhibits mold growth.

**Pros:**

* **Exceptional Stain Resistance:** SpectraLOCK Pro Premium Grout is highly resistant to staining from a wide range of substances, making it ideal for kitchens, bathrooms, and other areas prone to spills.

* **Superior Durability:** The epoxy-based formula creates a strong and durable grout joint that can withstand heavy traffic and harsh cleaning chemicals.

* **Consistent Color:** SpectraLOCK Pro Premium Grout maintains its color consistency over time, resisting fading and discoloration.

* **Chemical Resistance:** Resistant to a wide array of chemicals, making it ideal for commercial kitchens and labs.

* **Mold and Mildew Resistance:** The non-porous nature of the epoxy grout inhibits mold and mildew growth, promoting a healthier environment.

**Cons/Limitations:**

* **Higher Cost:** SpectraLOCK Pro Premium Grout is more expensive than traditional cement-based grouts.

* **More Difficult to Apply:** Epoxy-based grouts require more precise mixing and application techniques than cement-based grouts.

* **More Difficult to Clean Up:** Epoxy-based grouts can be more difficult to remove from tile surfaces than cement-based grouts.

* **Limited Color Selection:** While SpectraLOCK Pro Premium Grout is available in a range of colors, the selection is not as extensive as that of some cement-based grouts.

**Ideal User Profile:**

SpectraLOCK Pro Premium Grout is best suited for users who are willing to invest in a high-quality, long-lasting grout that offers superior stain resistance, durability, and color consistency. It is an excellent choice for high-end residential and commercial installations where aesthetics and performance are paramount.

**Key Alternatives:**

* **Custom Building Products Fusion Pro:** A single-component, stain-resistant grout that offers good performance and ease of use.

* **Mapei Ultracolor Plus FA:** A rapid-setting, polymer-modified grout that is ideal for time-sensitive projects.

**Expert Overall Verdict & Recommendation:**

Laticrete SpectraLOCK Pro Premium Grout is a top-of-the-line grout that delivers exceptional performance and long-term value. While it is more expensive and requires more careful application than traditional grouts, its superior stain resistance, durability, and color consistency make it well worth the investment for discerning users who demand the best. We highly recommend SpectraLOCK Pro Premium Grout for high-end residential and commercial tile installations.

Insightful Q&A Section

**Q1: What is the ideal mixing ratio for non-sanded grout, and how does it affect the final result?**

*A1:* The ideal mixing ratio for non-sanded grout is typically specified by the manufacturer on the product packaging. Generally, it involves adding a specific amount of water to the dry grout powder. Following the manufacturer’s instructions is crucial, as using too much water can weaken the grout and make it prone to cracking, while using too little water can make it difficult to work with and may result in poor adhesion. A properly mixed grout should have a smooth, creamy consistency that is easy to spread and tool.

**Q2: Can I use non-sanded grout on a shower floor, and what special considerations should I keep in mind?**

*A2:* Yes, non-sanded grout can be used on a shower floor, but it is essential to select a high-quality, polymer-modified grout that is specifically designed for wet environments. Ensure the grout is properly sealed to prevent water penetration and mold growth. Regular cleaning and maintenance are also crucial to prolong the life of the grout and prevent staining.

**Q3: How long should I wait before sealing non-sanded grout, and what type of sealer is recommended?**

*A3:* The waiting time before sealing non-sanded grout typically ranges from 24 to 72 hours, depending on the manufacturer’s recommendations and environmental conditions. It is essential to allow the grout to fully cure before applying a sealer. A penetrating sealer that is specifically designed for grout is recommended. This type of sealer will penetrate the pores of the grout and create a water-resistant barrier without changing the grout’s appearance.

**Q4: What are the common mistakes to avoid when applying non-sanded grout, and how can I prevent them?**

*A4:* Common mistakes to avoid when applying non-sanded grout include using too much water in the mix, applying the grout too thickly, and failing to clean the grout haze properly. To prevent these mistakes, carefully follow the manufacturer’s instructions, use the correct tools and techniques, and clean the grout haze promptly with a damp sponge.

**Q5: How can I remove stubborn stains from non-sanded grout without damaging the tile?**

*A5:* Stubborn stains can be removed from non-sanded grout using a variety of methods, depending on the type of stain. For mild stains, a mixture of baking soda and water or a mild detergent may be sufficient. For more stubborn stains, a grout cleaner specifically designed for removing stains from grout may be necessary. Always test the cleaner in an inconspicuous area first to ensure that it does not damage the tile.

**Q6: Is it possible to change the color of existing non-sanded grout, and what are the best methods for doing so?**

*A6:* Yes, it is possible to change the color of existing non-sanded grout using a grout colorant or stain. These products are designed to penetrate the grout and change its color without affecting the tile. Before applying a grout colorant, thoroughly clean the grout and remove any loose or damaged material. Apply the colorant according to the manufacturer’s instructions, and wipe away any excess from the tile surface.

**Q7: What is the difference between epoxy grout and non-sanded cementitious grout, and when should I use each type?**

*A7:* Epoxy grout is a two-part system that is made from epoxy resins and hardeners, while non-sanded cementitious grout is made from cement, pigments, and additives. Epoxy grout is more expensive than cementitious grout, but it offers superior stain resistance, durability, and chemical resistance. Epoxy grout is best suited for high-traffic areas, wet environments, and applications where chemical resistance is required. Cementitious grout is a more economical option for general-purpose tile installations.

**Q8: How do I prevent non-sanded grout from cracking, especially in areas with movement or vibration?**

*A8:* To prevent non-sanded grout from cracking, use a polymer-modified grout that is specifically designed for flexibility. Ensure that the substrate is properly prepared and stable before installing the tile. Use expansion joints in areas where movement or vibration is likely to occur. Properly mix and apply the grout according to the manufacturer’s instructions.

**Q9: Can non-sanded grout be used with all types of tiles, or are there any limitations?**

*A9:* Non-sanded grout can be used with most types of tiles, but it is particularly well-suited for use with delicate tiles, such as glass, polished stone, and certain types of ceramic and porcelain tile. It is not recommended for use with tiles that have very wide grout lines, as the grout may shrink and crack.

**Q10: What are the best practices for maintaining non-sanded grout to ensure its longevity and appearance?**

*A10:* Best practices for maintaining non-sanded grout include regular cleaning with a mild detergent and water, prompt removal of spills and stains, and periodic sealing to prevent water penetration and mold growth. Avoid using harsh chemicals or abrasive cleaners, as these can damage the grout and tile.

Conclusion & Strategic Call to Action

As we’ve explored, non-sanded grout is a crucial element in achieving beautiful, durable, and long-lasting tile installations. Its unique properties make it the ideal choice for narrow grout lines and delicate tile surfaces. By understanding its composition, advantages, and proper application techniques, you can confidently select and use non-sanded grout to create stunning results. Recent advancements in polymer technology have further enhanced the performance of non-sanded grout, making it an even more reliable and versatile choice for a wide range of tiling projects.

In our experience, the key to success with non-sanded grout lies in careful preparation, precise mixing, and meticulous application. By following the manufacturer’s instructions and paying attention to detail, you can avoid common pitfalls and achieve a professional-quality finish. Remember, selecting the right grout is just as important as selecting the right tile. By investing in a high-quality non-sanded grout and taking the time to apply it properly, you can ensure that your tile installation will look beautiful and perform flawlessly for years to come.

Now that you’re equipped with the knowledge to master non-sanded grout, we encourage you to put your skills to the test! Share your experiences with non-sanded grout in the comments below. Or, explore our advanced guide to tile setting for even more expert tips and techniques. Contact our experts for a consultation on non-sanded grout!